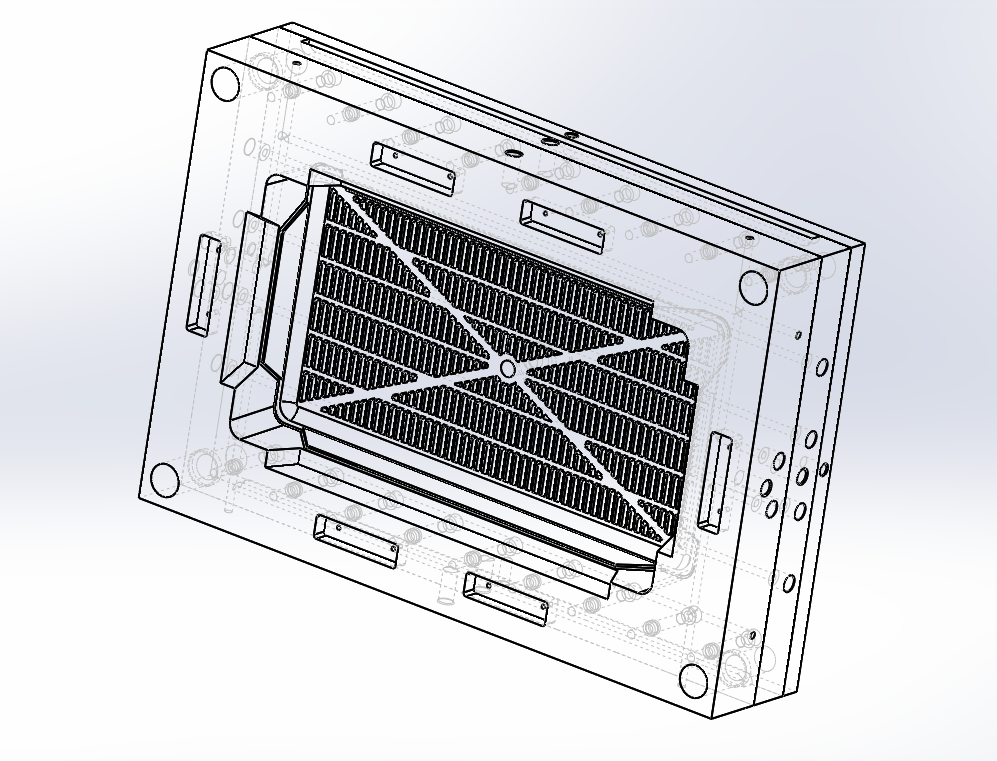

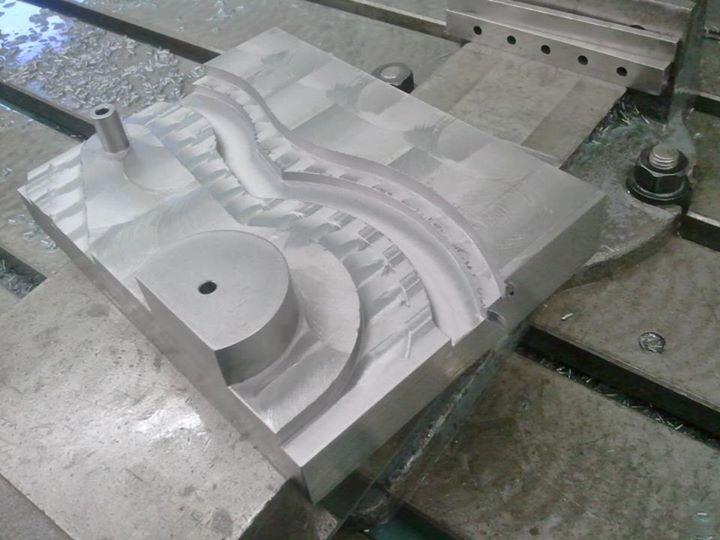

Design & Engineering

|

Our partners use the latest software and prototyping techniques to deliver your part design as quickly and efficiently as possible. Send us your file or let us help you create your design. We use Solidworks for design, and Mastercam for programming. While a .step file is ideal, we can accept many different file types. If desired, we offer a rapid turn-around time from .step file to a 3D printed part prior to making the mold.

|